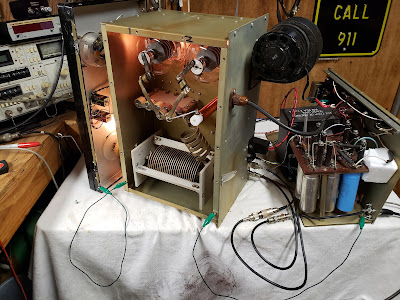

This is a Henry 2KD-Classic that came to me for an overhaul. A friend bought it off eBay, and it came in as a mess. It was shipped with the plate transformer installed (bad idea!), the cabinet was warped and twisted, wires broken, hv filter module barely held in place, filament transformer missing hardware and partially slung apart, had a broken fuse holder, wires and components twisted together, high voltage wire wrapped with electrical tape, taps broken from the tank coil, blower assembly, and rear panel flopping about, broken tube socket, etc. These things don't ship very well. Additionally, it needed recapping, some of the tuned input coils were broken off of the mounts, the output so-239 was broken loose from the cgassis, needed a plate relay, and a lot of work in the tank circuit. It's sad to see such a nice amplifier in this condition. I got it all back together and on the air. Here's a few pics and videos...

I've been in Amateur Radio since 1974, and still find new and interesting things to do. I like to build, restore, and operate on the air. This blog has been running for many years, so be sure to check out "Jump to Posts on Specific Topics" in the RH column to drill down and find lots of stuff. Visit www.WB4IUY.net, email to wb4iuy@gmail.com, or leave comments here directly on my blogs.

Tuesday, September 10, 2024

Friday, September 6, 2024

Working Australia from NC on 10m AM with Conv Cb

I keep this little rig on in the workshop, awaiting a band opening. Tonight, VK4VN in Brisbane, Australia was coming in. I called him, and he answered. Wow, not to shabby with a $5 radio!

Wednesday, September 4, 2024

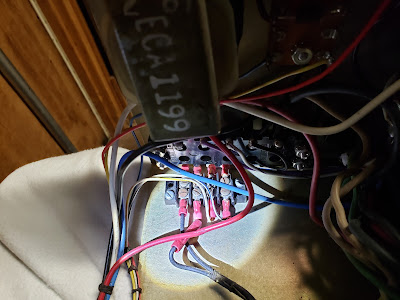

Dentron Clipperton-L

This is a Dentron Clipperton-L amp I rebuilt for a friend. I recapped it, beefed up the bias circuit, cleaned the t-r relay, and repaired a bad band switch wafer.

The band switch had melted the 15m & 10m contacts, carbon tracked the ceramic wafer, and the heat from arcing had cracked the ceramic. I tried a couple of sources for a replacement band switch, but couldn't get the correct fit. So, I used a dremel tool to cut the rivets from a good wafer and removed the contacts. I did the same to the bad wafer and removed the bad contacts. Then, using a sanding disc, I removed the carbon from the broken pieces of the bad wafer. Next, I re-assembled the wafer with Cyanoacrylate glue and accelerator. Using small machine screws and nuts, I re-installed the new contacts on the wafer, and reassembled the band switch.

I recapped with 105° C electrolytics. It required redrilling the OEM board, and remapping the lower tracing.

I also padded the pi-net loading circuits to allow the load control to load around 50%, something these seldom do on 160, 80, and 40m.

Now, she's back in the air and burning leaves off of the trees :-) Here's a few pics: