I found a nice set of Infinity 1001A speakers. The crossover adjustments were loose and needed cleaning. While inside, I replaced the np caps in the crossovers, due to age. These are low power speakers with rear firing tweeters. The power rating for the Infinity 1001 speakers is 8-50 watts RMS. The nominal impedance is 6 ohms, and the sensitivity is 89dB @ 1 watt, 1 meter. The frequency response is 70Hz-22kHz +/-3dB. Boy, do they sound nice!

WB4IUY's Random Blog

I've been in Amateur Radio since 1974, and still find new and interesting things to do. I like to build, restore, and operate on the air. This blog has been running for many years, so be sure to check out "Jump to Posts on Specific Topics" in the RH column to drill down and find lots of stuff. Visit www.WB4IUY.net for the lowdown at WB4IUY. Email me at wb4iuy@gmail.com if you have any questions.

Sunday, June 8, 2025

Friday, June 6, 2025

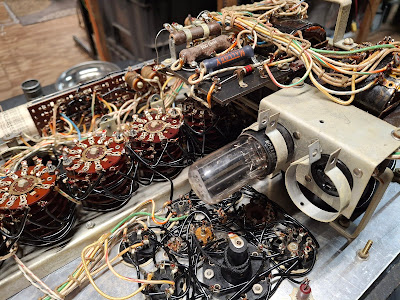

Hickok 536, pt2

This is part 2 of a Hickok I picked up. After some testing, I discovered some tests were way off. After disassembly and a quick check, I found the #83 rectifier to be very weak. I built a solid state replacement and fused it, and all was well. I also installed a 3-wire safety power cord, and began cleaning.

Thursday, June 5, 2025

D&A Phantom Repurposing...

Whilst on the road, I'll update this a bit. This will ultimately be a bandswitched 80-10m GI6B amplifier. This is pt2.. I finally finished refinishing the outer cabinet with a nice wrinkle black surface. The face & inner cabinet will be an Ivory White. Here's a few pics.

Firebird Amp, pt2

I'm using this time to upload some pics, while on the road. I made a bit of headway in repurposing and refinishing the cabinet from the old Firebird amp for the new build. Here's a few pics...

Sanding the inside of the rear panel...